Projects

Inverted Pendulum

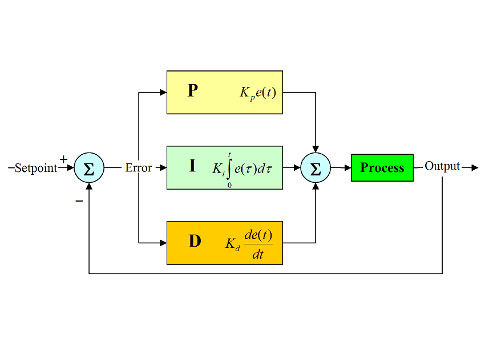

Proportional Integral

Derivative Controller

Constructed and programmed a bi-wheeled robot to balance itself upon the positive Z-axis by using Proportional Integral Derivative (PID) control

Control Loop Schematic:

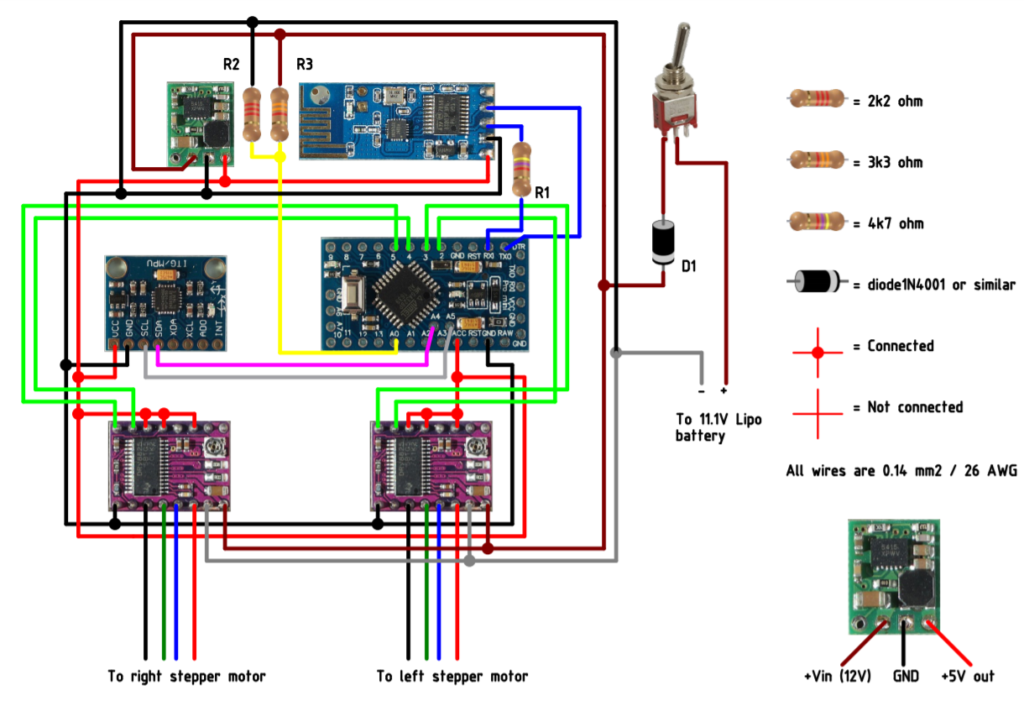

Circuit Schematic:

Parts List

Name | Manufacturer | Part Number | Purpose |

2 x NEMA 17 Stepper Motor | StepperOnline | 17HS16-2004S | Moves the wheels on the robots |

2 x 100mm Wheels | N/A | N/A | Allows the robot to move around and recover from pushes |

1 x MPU 6050 | FTCBlock | GY-521 | Calculates the angle of the robot’s frame relative to the ground |

1 x Arduino Nano | N/A | N/A | Calculates the changes in the wheels to make according to the internal PID and the Gyro readings |

Initialization

int gyro_address = 0x68; //MPU-6050 I2C address |

PID Calculations

pid_error_temp = angle_gyro – self_balance_pid_setpoint – pid_setpoint; |